-

Products

Featured Product

The XE360™ Series is the next generation wireless lock from Schlage, designed specifically for multifamily properties. It delivers innovation, intelligence and reliability wrapped in a modern, sleek design. Looking for more information about this smart and stylish solution? Our knowledgeable team is ready to help.

Credentials

From high-rise offices to hospitals and just about everything in between, building owners seek the security, convenience and efficiency of credentials for access control. With the latest in mobile, smart technology and traditional proximity technology, we have an option for every budget and business need.

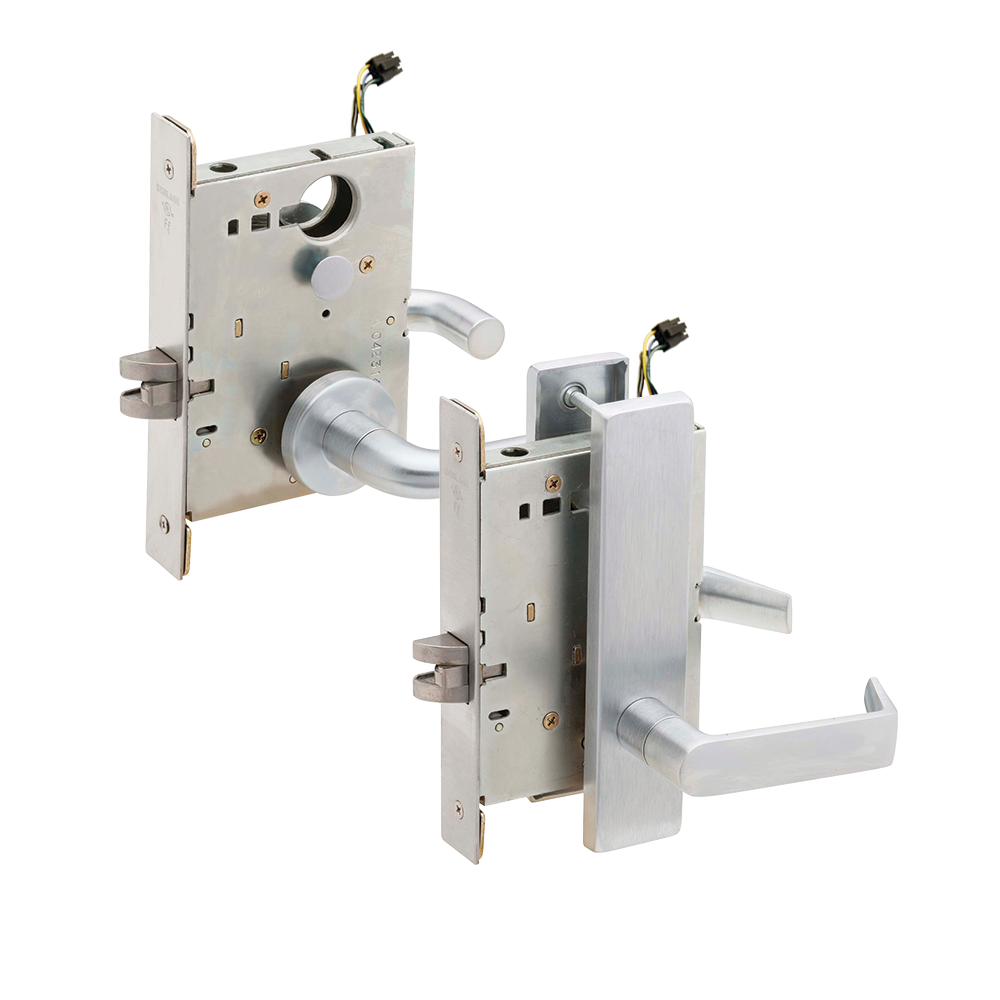

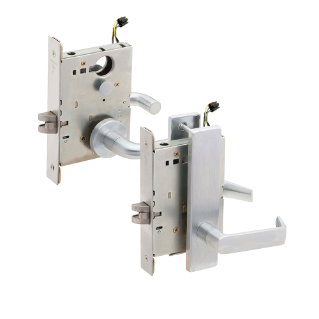

Electrified Locks

Electromechanical locks are a versatile Electronic Access Control (EAC) solution that can be managed locally by a card reader and controller or a simple remote release switch. They also offer a dependable, wired solution as part of a facility-wide EAC integration. Schlage offers multiple functions and a wide selection of finishes and designs in electrified mortise, mortise multi-point and cylindrical locks.

Electromagnetic Locks

Electromagnetic locks use magnetic force and have no moving parts making them highly reliable and an easy to maintain choice for fail-safe applications when code compliance permits.

Electronic Locks

Electronic locks are an all-in-one access control solution that make securing openings simpler and provide an increased level of intelligence and control. Schlage offers standalone, wired and wireless solutions for every application from a single door with simple access needs and budget all the way up to a complex campus or enterprise deployment.

Key Systems

Key systems are integral to maintaining building security, whether it’s during construction, changes in occupancy or daily use. Schlage offers a layered security approach to keying that lets you utilize a combination of open and/or restricted products alongside Primus cylinders all within the same keyway family to provide the right level of security for any entry. It’s innovative thinking that is flexible and upgradeable over time to fit your security needs well into the future.

Mechanical Locks

Schlage mechanical locks include best-in-class, Grade 1 solutions designed for strength and durability over time. Schlage quality goes beyond fit and function to deliver trim options that meet both aesthetic and security needs including lock status indication, health care trim solutions, and simply beautiful lock designs. Perfect suiting of the ND Series Grade 1 and ALX Series Grade 2 cylindrical locks helps you achieve a visually seamless look while saving money. In fact, all Allegion products are designed for visual compatibility across finishes to serve your whole building needs.

Power Supplies

Schlage provides a comprehensive line of UL 294 certified power supplies which can be outfitted with a variety of option boards to support functional capabilities.

Readers

Readers offer greater security by requiring personalized credentials to enter an area and can provide audit trails to show who accessed specific openings and when. With our versatile mobile enabled, multi-technology, smart and proximity reader options, we have a solution for any physical access control need.

Reader Controllers

Reader controllers combine reader technology together with the intelligence of a controller to provide a solution that can interface with an electrified lock, electric strike, exit device or automatic operator for common area and perimeter applications.

Software

Software is at the heart of Electronic Access Control solutions; it is used to commission devices, manage doors, add users, and assign access privileges. Allegion offers access control software for low to medium complexity applications. For enhanced features and capabilities, choose a solution from one of our leading physical access control software (PACS) providers or multifamily technology alliances.

System Accessories

Schlage system accessories include a variety of devices that easily integrate with most existing security systems to enable specific functionality whether in standalone applications or as part of networked electronic access control systems. -

Solutions

By Market

Find the right solutions for your K-12, health care, higher education, multifamily, government and commercial real estate projects.

By Role

Are you an architect, facility manager, general contractor, locksmith, security consultant, security integrator or channel partner? We have resources to support your locking hardware and access control solutions requirements.

By Requirement

Explore solutions for specific requirements including high security, lockdown capable, severe weather, and electronic access control.

By Family

Schlage offers a comprehensive range of commercial locks designed to meet the diverse security needs of modern businesses and institutions. Their product families provide scalable, flexible, and secure access control solutions tailored to different operational requirements and facility types. - Resources

- Why Schlage